TANK WATERPROOFING

- Home

- Tank Waterproofing

TANK WATERPROOFING

Waterproofing your commercial or industrial tanks is essential to maintaining a leak-free water storage system. Minor cracks or leaks within waterproofing membranes can rapidly lead to major structural issues, flooding, electrical hazards and a range of unforeseen compliance breaches.

As well as tanks themselves, oftentimes immediate areas surrounding tanks, or areas that are frequently exposed to unsought spillages also require waterproofing solutions.

Raven Tanks have the expertise, equipment and resources to install a variety of different membrane types to suit all sites and industrial tank setups.

What Are Waterproofing Membranes?

Heavy-duty tank waterproofing membranes are fundamentally a ‘film’ or a coating applied to surfaces to prevent water from seeping into undesired areas.

These can be applied in many ways however it’s important to ensure the membrane type you’re installing is effectively suitable for its particular application.

Raven Tanks have been installing tank waterproofing systems for over three decades, recommending and applying membranes to support endless applications across Australia.

Waterproofing Membrane Types We Apply

Tank waterproofing membranes are available in a number of application types with Raven Tanks supplying a range of high-grade peel and stick, torch-on and liquid products to enhance your tank’s storage capabilities.

Types of tank waterproofing membranes we apply include:

- Torch-on Membranes (single and double-layered) – A low-maintenance membrane solution consisting of bitumen and modified polymers. There are two types of torch-on membranes – Atactic Polypropylene Plastic (APP) and Styrene Butadiene Styrene (SBS).

APP membranes are best utilised in tanks exposed to consistent sunlight and extreme temperatures. It comes in sheet form and is easily melted on using heat. SBS membranes are more suitable for cold climates where less expansion of the tank’s surfaces occurs.

- Peel and Stick Membranes – Generally used on vertical surfaces, self-adhered waterproofing membranes are a ‘film-like’ material with a simple, stick-on application method. More suitable to metal tanks for longer-lasting adhesion.

- Liquid Membrane Applications – A sealant-style gel-like coating designed to prevent/fill any microscopic leaks presenting the potential for major future issues. It’s easily spayed on and is a high-strength, cost-effective waterproofing solution.

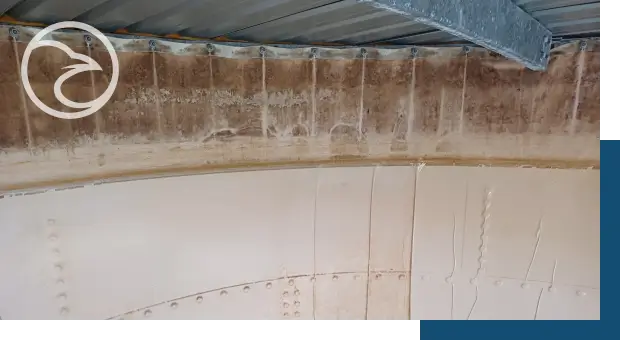

Concrete Tank Applications

Concrete based or walled tanks generally require a liquid barrier solution. This is usually the most appropriate protective layering method and often needs two coats to maximise its effectiveness.

Cracked containments are a common problem needing a membrane solution that’ll essentially ‘seal’ vulnerable surface areas.

Raven Tanks uses liquid polyurethane coatings on tanks and water storage areas with concrete surfaces for an enhanced level of long-lasting waterproofing protection.

Arranging An Inspection – Why It’s Important

Keeping up to date with your tank’s condition status allows you to understand, acknowledge and plan for preventative maintenance works. Water leakages aren’t always noticeable to the untrained eye taking long periods to develop, worsen and present as an obvious danger.

Also, water incrementally leaking onto access platforms, walkways and other high foot traffic areas poses as a hazard and a safety liability should an accident occur caused by a neglected water storage system.

Contact Raven Tanks’ waterproofing team today to discuss our services, accreditations and for any other questions or tank-specific enquiries you may have!

- NEED A QUOTE?

Get in touch

Contact the Raven Tanks team to discuss maintenance requirements and pricing structures for our entire panel tanks range today!