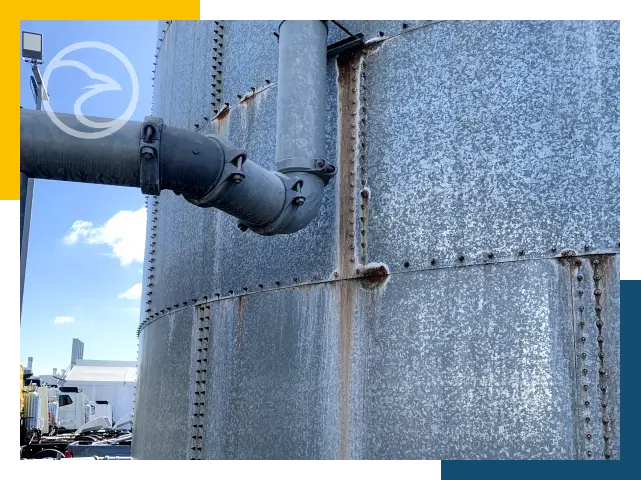

Professional Water Tank Maintenance Services

Tank Maintenance

Arranging preventative maintenance to be regularly carried out on your tanks is critical to ensuring your liquid storage systems remain safe and are in optimum working order.

Although primarily precautionary, having scheduled maintenance performed on your tanks by industry leaders significantly reduces the risks of leaks, equipment faults and future system failures.

With increasing emphasis being placed upon standards, legislation and responsibilities surrounding our industry, understanding tank ownership requirements has never been more important.

Learn more about tank maintenance and the specific services Raven Tanks specialise in below.

Learn how to save up to 30% on installation and maintenance — fill out the form now!

Routine Maintenance – Inspections, Cleaning & Repairs

Raven Tanks inspect, clean and maintain all elements of your potable water tanks, fire tanks and non-potable liquid containment systems in accordance with Australia’s industry standards.

Our team will assess your entire tank unit determining the most appropriate course of action regarding any detected leaks, faults or outdated equipment proving potentially hazardous.

We also carry out high-pressure surface cleaning procedures helping manage corrosion and keep your tanks and their contents in exceptional condition.

Signage

We supply and install all tank signage as per national compliance requirements.

Fire tank systems must display the following colour-coded signs in their respective dimensions, with Raven Tanks capable of affixing each:

- Capacity signage

- Contents signage

- Potable/Non-potable water signage (Do Not Drink)

- Level Indicator signage

- Warning and locational indicators

Tank Fixtures & Components

Repairs are often the next best maintenance alternative to fully replacing internal tank parts such as panels, ladders and connective equipment.

Restoring a tank’s fittings ensures the system operates in a satisfactory condition, perfect for meeting mandatory compliance criteria.

Revamping the existing hardware is generally less expensive while still offering remarkable, remodelled performance.

Level Indicators

Different tank types require different sorts of level indicators. We can custom-supply panel tank level indicators to suit a number of industry-specific systems and applications.

These use sensory technology to identify highly accurate contents levels and is essential to maximising your tank’s operational efficiency. Eventually, indicative sensors deteriorate and fail to correctly read the substances contained in your tanks.

Level indicator maintenance and replacement are the more effective methods of avoiding the inconvenience of a major shutdown caused by a total malfunction.

Raven Tanks’ ROV Technology – The Benefits

While our commercial dive team are ultra-effective at conducting precision testing and delivering impeccable results, Raven Tanks’ ROV (Remotely Operated Vehicle) services provide us with a prototypical insight into your tank’s condition.

Here’s why we recommend ROV maintenance services for your liquid storage systems:

- It’s more conservative – No need to drain your tanks, avoiding detrimental wastage

- Safety – Humans won’t be required to enter your tanks reducing the risk of harmful chemical or bacterial exposure

- Your tanks remain online and accessible during cleaning

- No notification processes required – Utilising dive teams involves you having to inform several organisations, authorities and emergency services prior to draining and cleaning. Not anymore!

Why have Raven Tanks maintain your water storage systems?

Improperly tested tanks pose risks — trust experienced pros for reliable inspection. Here’s why Raven Tanks is your top choice for maintenance:

- Comprehensive repairs for any tank — any type, size, location, or contents.

- Fully licensed technicians — certified for safe Confined Space and Working at Heights tasks.

- We offer cost-effective tank repair solutions to accommodate all budgets.

- All works are Australian Industry and Standard-compliant.

- Emergency Response Support – We’re here when you need us!

Client Questions – Our Answers

We know our clients often have important questions before starting a project. Here are clear answers to help you make informed decisions with confidence.

Signs your water tank needs cleaning include unpleasant odours, discoloured water, visible sediment, or reduced water flow. Regular inspections every 6–12 months help catch issues early and prevent contamination.

The best method includes draining the tank, removing sludge manually or with pressure washers, disinfecting with a suitable chemical (like chlorine solution), and rinsing thoroughly. Always follow safety protocols, especially in confined spaces.

Domestic water tanks should be cleaned every 6 to 12 months. Commercial or rainwater tanks may require more frequent maintenance depending on usage, location, and exposure to contaminants.

To maintain a stainless steel (SS) water tank effectively, it’s important to inspect it regularly for any signs of corrosion or structural damage. Cleaning should be done at least twice a year to remove sediment or biofilm buildup. Using a secure tank cover helps keep out insects, leaves, and other contaminants.

- NEED A QUOTE?

Get in touch

Tanks due for their routine inspection again? Contact the Raven Tanks team to schedule your annual, bi-yearly or ten-yearly maintenance examination today!