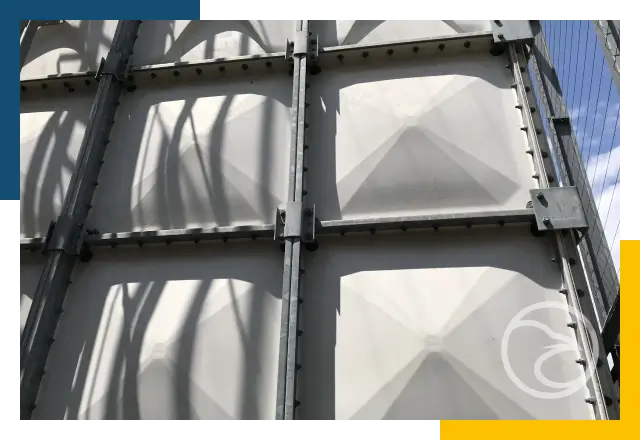

When standard cylindrical storage isn’t an option, Square Panel Tanks and Rectangular Panel Tanks provide the ultimate spatial efficiency. Engineered for tight footprints like basements, plant rooms, and industrial corridors, these modular systems maximize every cubic meter of your available space.

At Raven Tanks, we design and supply custom-configured rectangular panel tanks that combine modular flexibility with high-load structural integrity, ensuring a perfect fit for even the most restricted sites.

Backed by our comprehensive structural design capabilities, we provide fully customized assembly and design solutions for complex urban and industrial environments.

Unlike standard round tanks, rectangular panel tanks are engineered to utilize every square meter of your available space. They are the ideal solution for:

We manufacture square panel tanks using premium materials to ensure longevity in any environment:

Square and rectangular panel tanks are suitable for a wide range of applications, including:

Their modular design allows efficient installation even in confined or challenging locations.

Our approach to rectangular panel tanks focuses on structural integrity and leak-proof performance. Every project includes:

To maintain structural rigidity, our rectangular panel tanks are engineered with two primary bracing options depending on your site requirements:

Utilizes stainless steel or galvanised rods inside the tank to hold the walls together. This is the most space-efficient option, allowing the tank to be placed flush against building walls.

Uses heavy-duty steel beams on the outside of the tank. This leaves the interior completely clear for easier cleaning and maintenance, though it requires additional clearance around the tank’s perimeter.

At Raven Tanks, we support your project from design to installation. Our team assists with tank layout, capacity planning, and configuration to suit site conditions and compliance requirements.

Once the final design is approved, tanks are typically delivered within 6 weeks, with installation completed in 1–4 weeksdepending on size and location. Timelines may vary based on project scope.

For specific delivery or installation requirements, our team is ready to assist.

We know our clients often have important questions before starting a project. Here are clear answers to help you make informed decisions with confidence.

Yes, their modular nature allows us to transport components through standard access points and assemble the tank entirely on-site.

Our modular systems are highly scalable, ranging from small 5kL units to large-scale industrial reservoirs exceeding 1,000kL.

We use internal stay-rods or external heavy-duty steel bracing (depending on your preference) to ensure the walls remain perfectly rigid under full hydraulic load.

Our designs include dedicated internal or external ladders and roof hatches. Because of the modular square panel tank design, individual sections can be inspected or replaced without needing to decommission the entire system.

Upgrade to a high-efficiency square panel tank solution today. Contact Raven Tanks for a custom design quote and engineering consultation tailored to your facility’s needs.